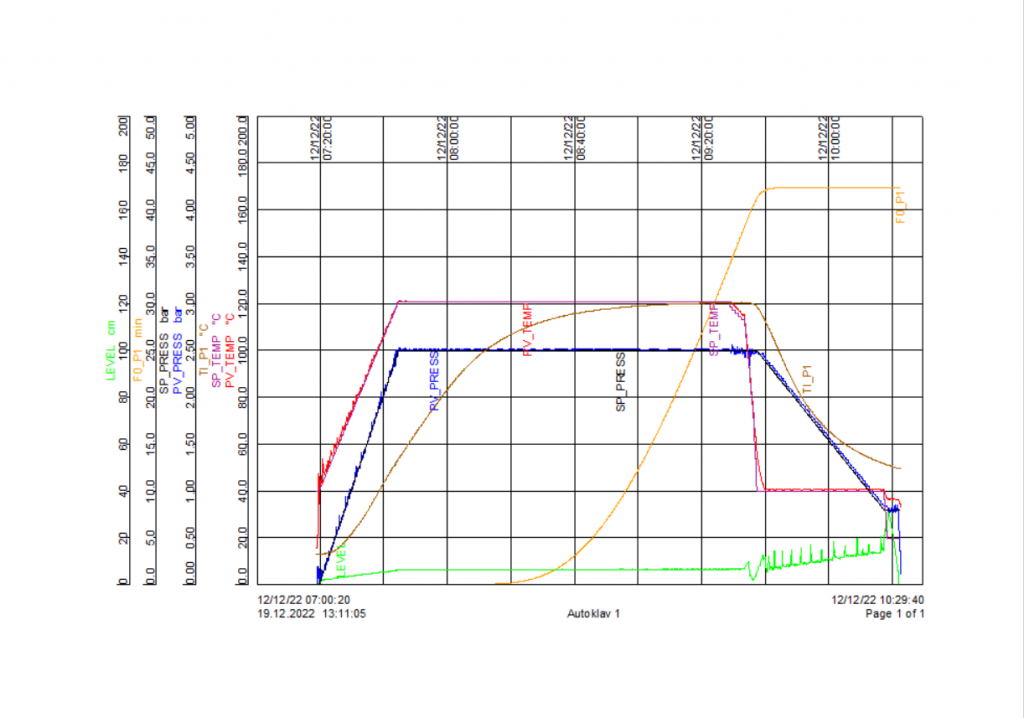

Safety is probably the most guarded aspect of manufacturing these days. It is of course crucial for us as well. The longer and the higher the temperature you sterilise the product at, the greater the assurance of safety. On the other hand, however, such production is more expensive and the product is then inferior in quality. The meat breaks down more, is more cuddly, releases more liquid. Whereas before we used to sterilize with constant long endurance, today we can set the sterilization to a completely safe, but at the same time much less destructive level of heat and pressure sterilization thanks to the probe directly in the product and the automatic calculation of F0 values. Today, a newly installed telemetry system records these values every second of autoclave operation, giving us accurate data on the sterilization process for the entire expiration period of the product. This increases both traceability and safety, as well as the quality and efficiency of the operation!